Carbide tip bits have gained significant attention in various industries due to their ability to handle tough materials and maintain performance over time. These bits, known for their wear resistance, are often used in environments where conventional steel bits may struggle to maintain sharpness or structural integrity.

The primary advantage of using a carbide tip bit lies in the hardness and heat resistance of the carbide material. These characteristics allow for efficient penetration into surfaces such as hardened steel, concrete, masonry, and stone. This versatility makes them valuable in construction, manufacturing, and even specialized DIY tasks.

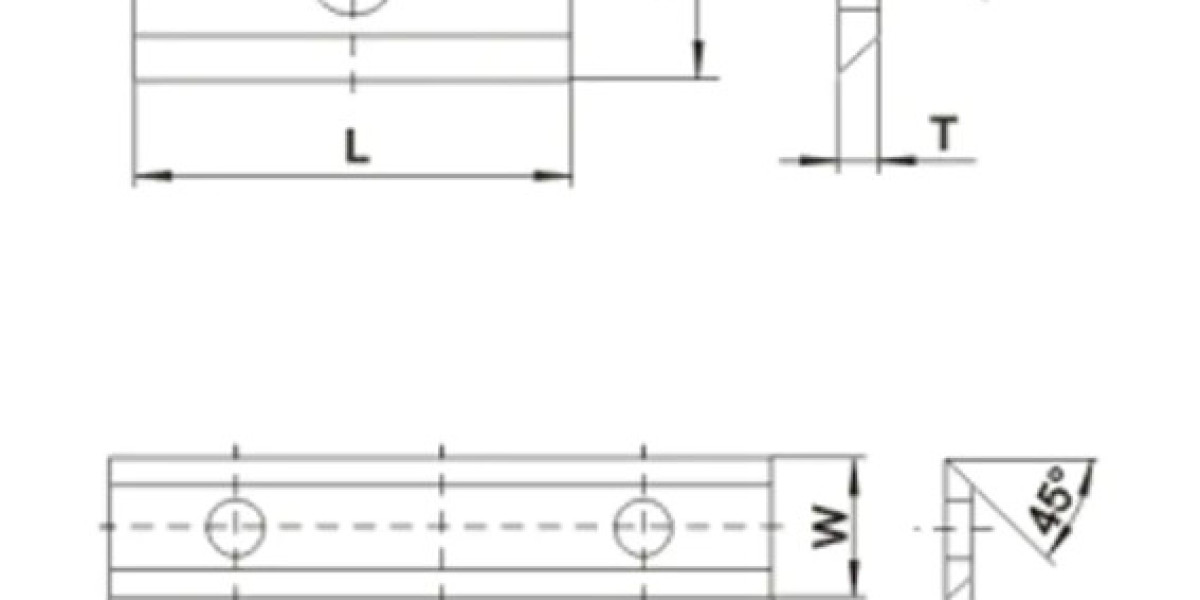

When choosing a carbide tip bit, it's important to consider the intended application. For example, drilling through reinforced concrete may require a specific bit shape or size to prevent chipping or breakage. Carbide tip bits can come in various geometries, each designed for a specific type of cut or drill path. Proper matching of the bit with the material ensures safer and smoother operation.

Another factor to consider is the drill speed and pressure. Although carbide tip bits are durable, excessive force or inappropriate speed may lead to overheating or dulling. Using suitable coolant or controlling drill cycles can extend the lifespan of the bit significantly. Regular inspection and proper storage also help maintain tool condition.

Carbide tip bits are often integrated into rotary hammer drills or impact tools for maximum efficiency. Their ability to retain edge sharpness allows them to perform consistently across long projects. This consistency reduces downtime and tool replacement, which is particularly important in commercial or industrial settings.

Overall, carbide tip bits provide a reliable solution for applications that involve dense or abrasive materials. Understanding their characteristics and limitations helps users maximize efficiency and safety during drilling tasks.