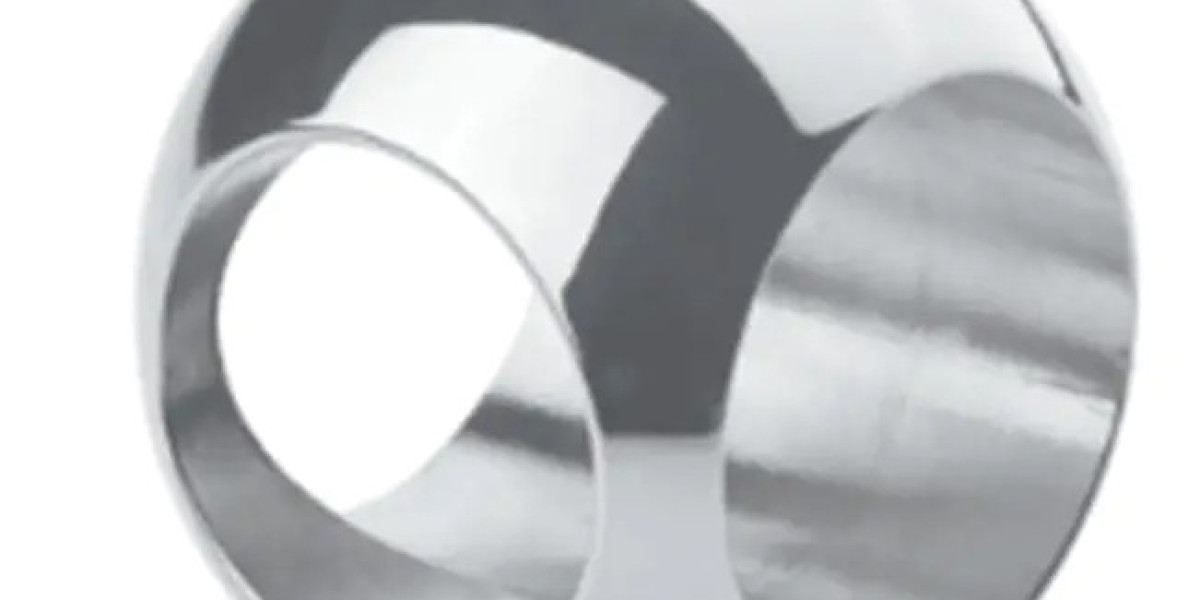

Straight ball valves are widely used in various industries for controlling the flow of fluids. The design consists of a spherical ball inside the valve body that rotates to open or close the passage. When the hole in the ball aligns with the pipe, fluid flows freely; when rotated 90 degrees, the flow is blocked. The straight design of this valve means the inlet and outlet ports are in a line, creating a direct route for the fluid.

One of the reasons straight ball valves are common is their ability to handle a variety of fluids, including water, oil, gas, and chemicals. Depending on the materials used for the ball and body, these valves can be adapted for different pressure and temperature conditions. The simple on-off operation allows for quick response in emergency shutoff situations.

The compact structure of straight ball valves makes them easy to install in piping systems with limited space. Additionally, the valve requires minimal force to operate, thanks to the smooth movement of the ball. This can reduce wear on the actuator or handle, contributing to longer valve life.

While generally low maintenance, straight ball valves still require periodic checks to ensure seals remain intact and the ball surface is free from corrosion or debris. Any buildup can affect sealing performance, leading to leaks or flow restrictions. Cleaning and replacing worn parts as needed can help maintain proper function.

Overall, straight ball valves provide a dependable solution for fluid control. Their straightforward mechanism, ease of use, and compatibility with various materials and fluids contribute to their ongoing popularity. Selecting the right valve for the specific operating environment is essential for achieving consistent performance.