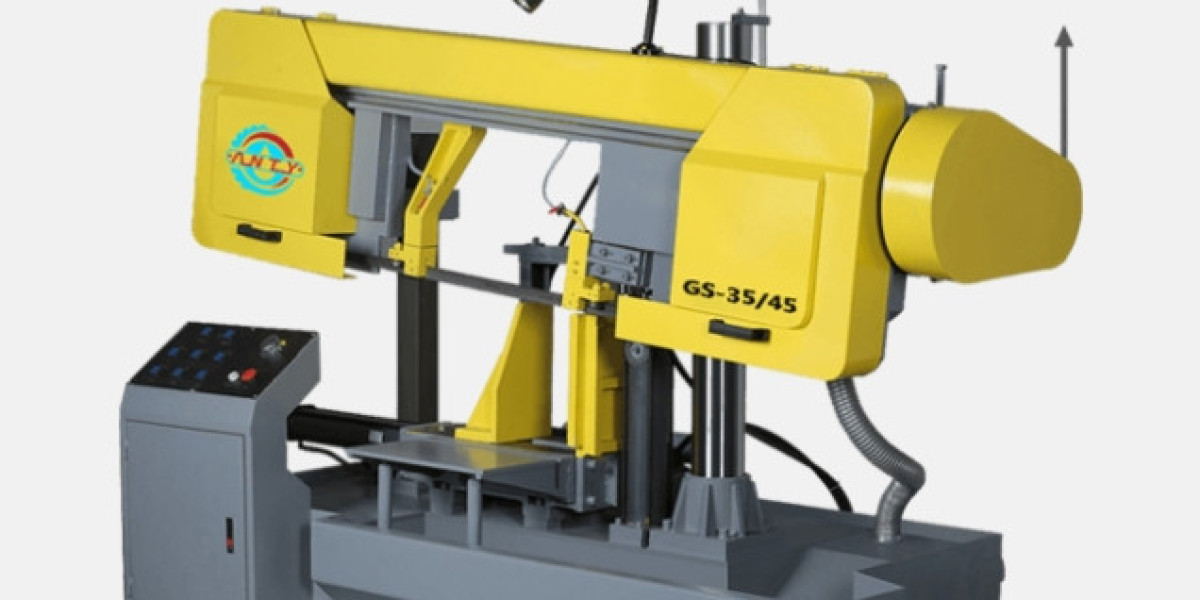

A Horizontal Metal Cutting Band Sawing Machine is an essential piece of equipment in metalworking industries. Its design enables accurate horizontal cuts through a wide range of metal materials. From small workshops to large-scale manufacturing environments, this type of saw is widely appreciated for its ability to deliver consistent and dependable results.

The effectiveness of any band saw depends significantly on its construction. In horizontal models, the structural stability of the frame is a priority. A rigid frame reduces vibration, which directly improves cut quality. Excessive vibration can cause blade drift or rough surfaces, both of which may require further finishing steps.

Another key feature is the hydraulic feed system. This mechanism controls the speed at which the blade descends through the material. In many models, this feed rate can be adjusted to suit different materials, which helps preserve blade life and ensures smooth cutting. For example, softer materials like aluminum can be cut at higher speeds, while slower feeds are recommended for hardened steels.

The Horizontal Metal Cutting Band Sawing Machine is also commonly equipped with adjustable blade speed. This flexibility allows operators to optimize the machine for various tasks, reducing wear on components and achieving better results. The ability to change speeds easily means that one machine can be used for several material types without needing separate equipment.

Clamping systems are another important component. Proper clamping prevents movement during cutting, improving precision and safety. Most machines use a hydraulic or manual vise to secure the material in place. This helps maintain uniformity, especially when cutting multiple workpieces to the same length.

Coolant systems play a supporting but essential role. During operation, friction between the blade and material generates heat. Without a proper cooling system, the blade can overheat and degrade quickly. A coolant flow not only cools the blade but also helps clear metal chips from the cutting zone, reducing blade binding and promoting smoother cuts.

The machine’s cutting capacity—defined by its throat depth and maximum height—is also worth noting. Businesses that work with large diameter pipes or structural beams should select a machine with enough capacity to handle their typical workload. Likewise, machines with automatic shut-off or programmable cutting cycles are helpful in production environments where efficiency and repetition matter.

Whether used for one-off custom pieces or continuous production runs, the Horizontal Metal Cutting Band Sawing Machine offers a practical solution. It combines straightforward operation with the ability to meet demanding precision standards. Operators with even basic training can become proficient in using the machine, thanks to its intuitive setup and stable cutting mechanics.

Investing in a machine with the right features and capabilities can result in long-term benefits. Reduced downtime, lower blade consumption, and consistent cutting quality contribute to a smoother production process. For companies seeking equipment that balances functionality with operational control, the horizontal band saw is a reliable option.